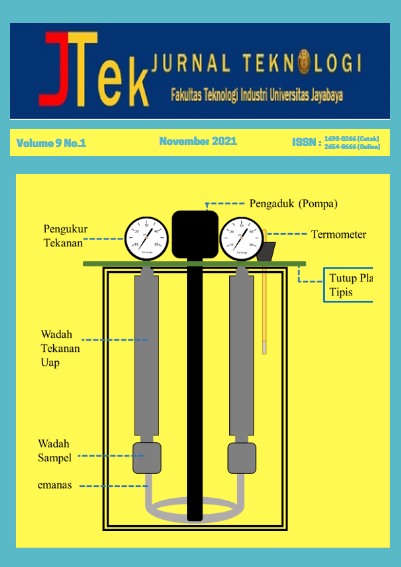

Analisis Perbandingan Jenis Material Penukar Kalor Plat Datar Aliran Silang Untuk Proses Pengeringan Kayu

DOI:

https://doi.org/10.31479/jtek.v9i1.117Keywords:

flat plate heat exchanger, heat transfer coefficient overall, effectivenessAbstract

The processed wood industry urgently needs a dryer to improve the quality of its production. One of the important components in a dryer is a heat exchanger. To support a durable heat transfer process, a superior material is needed. The aim of the study was to analyze the effectiveness of the application of cross-flow flat plate heat exchangers to be used in wood dryers and compare the materials used and simulate heat transfer on cross-flow flat plate heat exchangers using Computational Fluid Dynamic simulations. The results showed that there was a variation in the temperature out of dry air and gas on the flat plate heat exchanger and copper material had a better heat delivery by reaching the temperature out of dry air and gas on the flat plate type heat exchanger of successive cross flow and. overall heat transfer coefficient value and the effectiveness value of the heat exchanger of the heat transfer characteristics that occur with the cross-flow flat plate type heat exchanger in copper material of 251.74725 W/K and 0.25.Downloads

References

B. Zohuri, Compact heat exchangers: Selection, application, design and evaluation, no. September 2017. 2016.

B. Agus Ismanto and D. Martono, “Pengawetan Warna Kayu Tusam ( Pinus merkusii ) Dan Pulai ( Alstonia sp .) Dengan Menggunakan Bahan Dasar Disinfektan,” J. Penelit. Has. Hutan, vol. 30, no. 2, pp. 155–162, 2012.

M. Al-Arabi and M. K. El-Riedy, “Natural convection heat transfer from isothermal horizontal plates of different shapes,” Int. J. Heat Mass Transf., vol. 19, no. 12, pp. 1399–1404, 1976, doi: 10.1016/0017-9310(76)90069-7.

I. Martorell, J. Herrero, and F. X. Grau, “Natural convection from narrow horizontal plates at moderate Rayleigh numbers,” Int. J. Heat Mass Transf., vol. 46, no. 13, pp. 2389–2402, 2003, doi: 10.1016/S0017-9310(03)00010-3.

A. A. Ibrahim, P. L. Chong, V. S. Rajasekharan, M. M. Ali, O. S. Zaroog, and A. N. Oumer, “Investigation of the effect of different materials on convective heat transfer,” J. Mech. Eng. Sci., vol. 14, no. 2, pp. 6642–6651, 2020, doi: 10.15282/JMES.14.2.2020.08.0520.

F. Kreith, Principles of Heat Transfer, Seventh Edition, vol. 55, no. 5. Cengage Learning, Inc., 2011.

L. Ode, M. Firman, A. Sonjaya, B. M. Suyitno, and A. Riyadi, “Cross-Flow Flat-Plate Heat Exchanger Using Computational Fluid Dynamics Simulation on Wood Drying Chamber,” Turkish J. Comput. Math. Educ., vol. 12, no. 10, pp. 7105–7115, 2021.

I. G. L. La Ode Mohammad Firman, “Alat penukar kalor untuk mesin pengering RDF,” Teknobiz, vol. 9, no. 3, pp. 14–19, 2019.

J. P. Holman, Heat Transfer, Tenth Edition, 10th ed. The McGraw-Hill Companies, Inc., 2010.

S. Kakaç, H. Liu, and A. Pramuanjaroenkij, Heat Exchangers: Selection, Rating, and Thermal Design, 3rd ed. Taylor & Francis Group, LLC, 2012.

Downloads

Published

Issue

Section

License

The rights of publication and use of intellectual works in this journal are the full property of the publisher, while the moral rights belong to the author.

The formal legal aspects of access and utilization of each Journal of Technology articles are subjected to the Creative Commons Attribution-Share Alike (CC BY-SA) license, which means that journal content can be used freely and fairly (fair use) in a similar form even for commercial purposes.

To avoid malpractice and plagiarism in publication of article publishing, the author is asked to fill out and sign a copyright statement on the Declaration of Authenticity of the Manuscript and Copyright Transfer.